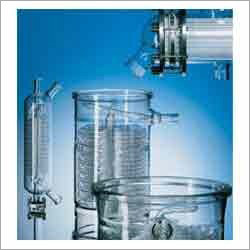

Glass Reactor

Price 5000 INR/ Box

MOQ : 1 Liter

Glass Reactor Specification

- Speed Range

- 50 1400 RPM

- Power Supply

- AC Power

- Heating Capacity

- 500W 3000W

- Shape

- Cylindrical

- Display Type

- Digital Display

- Accuracy

- 1C (Temperature control)

- Glass Type

- Borosilicate Glass 3.3

- Control Type

- Digital/Manual

- Features

- Anti-corrosive, Leakproof, High Transparency, Easy to Clean, Explosion Proof

- Temperature Resistance

- -80C to +250C

- Type

- Glass Reactor

- Dimension (L*W*H)

- Customizable as per requirement

- Equipment Type

- Laboratory Reactor

- Equipment Materials

- Borosilicate Glass, Stainless Steel

- Power

- 500W 3000W (depending on model)

- Voltage

- 220V/110V AC

- Material

- Borosilicate Glass 3.3

- Application

- Chemical synthesis, pharmaceuticals, research, laboratories

- Capacity (Ltr)

- 5 L to 100 L (depending on model)

Glass Reactor Trade Information

- Minimum Order Quantity

- 1 Liter

- Supply Ability

- 5 Liters Per Week

- Delivery Time

- 7 Week

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

About Glass Reactor

Glass Reactor

Technical Specifications

- Reactor Volume: 5L , 10L

- Reactor Type : Double Walled

- operating Pressure : Full Vacuum to 0.4 bar (g)

- Operating Tempt : -80°C to +200°C

- Thermal Shock Resistance ( T) : 110°C

Customizable Versatility for Every Application

Select from a wide range of capacities, mounting styles, and configurations to meet your research or production needs. Whether you require a benchtop setup for small-batch synthesis or a floor-mounted reactor for scale-up, our glass reactors can be tailored for laboratory, pharmaceutical, or chemical processing.

Robust Construction for Optimal Performance

Manufactured from high-clarity Borosilicate Glass 3.3 and stainless steel, these reactors provide superior thermal and chemical resistance. The anti-corrosive and leak-proof design ensures longevity, cleanliness, and operational reliability. Multiple neck ports make integration of probes, sensors, and accessories convenient.

Precise Control and Safe Operation

Achieve accurate temperature management (-80C to +250C) with advanced digital or manual controls and a temperature control accuracy of 1C. Variable speed agitation supports a range of reactions while explosion-proof construction and PTFE sealing enhance safety during operation.

FAQs of Glass Reactor:

Q: How do I choose between a jacketed and a non-jacketed glass reactor?

A: Select a jacketed glass reactor if you require precise temperature control using circulating fluids for heating or cooling. Non-jacketed reactors are suitable for processes where external temperature management is not necessary.Q: What is the process of setting up a glass reactor for a new application?

A: Begin by selecting the appropriate capacity and agitator type based on your application needs. Mount the reactor on a suitable stand, connect the required sensors and probes through the lid ports, and install any optional accessories such as condensers or dropping funnels. Set your temperature and agitation parameters using the digital control panel.Q: When should I use PTFE-coated versus stainless steel stirrers?

A: Use PTFE-coated stirrers for corrosive chemical reactions or applications requiring non-reactive surfaces, while stainless steel stirrers are ideal for general-purpose mixing where chemical compatibility is not a concern.Q: Where can I integrate sensors or sampling devices in the glass reactor?

A: The reactor lid features multiple necks, allowing you to conveniently install pH or temperature probes, sampling devices, and other instrumentation as required for your process.Q: What are the benefits of using a borosilicate glass reactor?

A: Borosilicate glass reactors offer high transparency for process observation, superior chemical resistance, and excellent thermal shock resistance. They are also easy to clean and maintain, ensuring repeatable and safe operations.Q: How is safety ensured during operation of the glass reactor?

A: The reactors are equipped with PTFE mechanical seals for leakproof operation, explosion-proof design features, and variable speed motors for controlled agitation. Digital temperature controls add another layer of process safety.Q: Can the reactor be customized for specific laboratory requirements?

A: Yes, reactors are fully customizable in terms of dimensions, capacity (5L to 100L), agitation type, sensor ports, and optional accessories, ensuring compatibility with a wide range of laboratory processes and research needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Glassware Category

Thin Film Evaporator

Type : Evaporator, Other

Material : Glass and metallic components

Application : Distillation concentration and purification of liquids

Features : Compact design efficient heat transfer low operating pressure

Warranty : 12 years standard warranty

Glass Nutsche Filters

Type : Other, Nutsche Filter

Material : Stainless Steel and Glass

Application : Chemical Pharmaceutical and Fine Industries

Features : CorrosionResistant Easy Maintenance Portable

Warranty : 12 Months

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS